WHEEL HUBS 101- Get About This Few Important Component

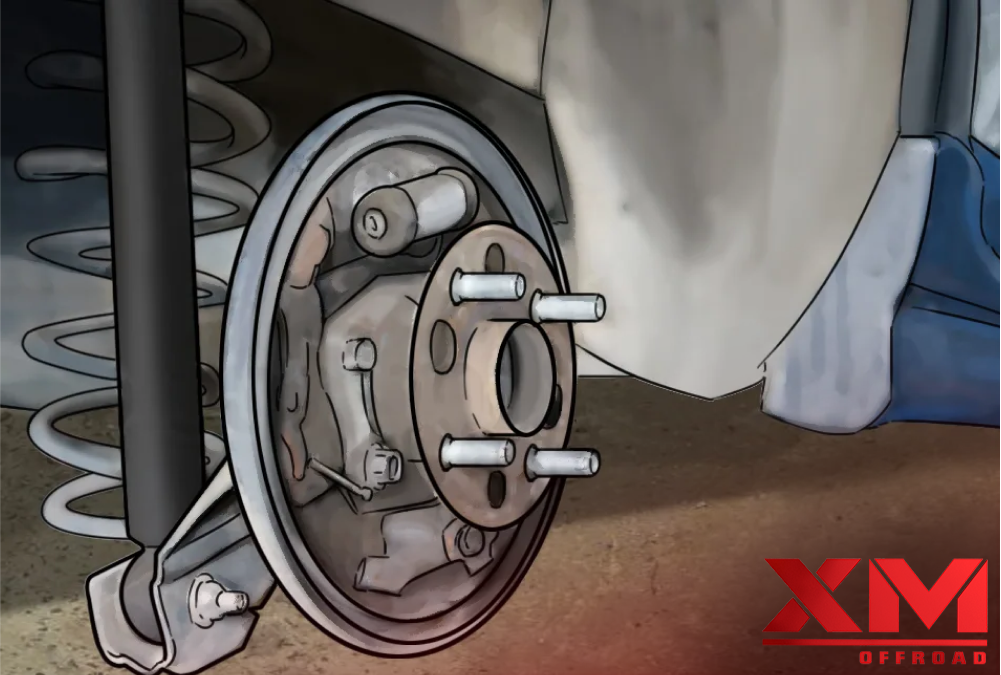

The wheel hubs is a crucial component that allows your vehicle to turn. It also helps reduce friction, which can help with fuel efficiency.

A car’s wheels spin about 840 times per minute. That much friction can cause a lot of heat and wear. Knowing how your wheel bearings and hub assemblies work can help keep them in good condition.

While a wide variety of wheel sizes are available for racing vehicles, 22 inch wheels offer a great balance between performance and cost. This size is ideal for reducing weight while maximizing stability and handling. Additionally, the larger diameter of these wheels allows for increased traction and a smoother ride. Ultimately, the decision to use 22 inch wheels is a personal one that must be made based on each driver’s specific needs and preferences.

Components of a Wheel Hub Assembly:

Next, a wheel hub assembly consists of several crucial components that work together to support the wheel and facilitate smooth rotation. These components include:

- Wheel Bearings:

Wheel bearings are crucial for reducing friction and rotating the wheel smoothly. They are housed within the wheel hub assembly, allowing the wheel to spin freely around the axle.

-

Hub Flange:

The hub flange is a flat, disc-like component located at the centre of the wheel hub assembly. In addition, it provides a mounting point for the wheel and ensures a secure attachment.

-

Studs or Bolts:

Studs or bolts are threaded fasteners that secure the wheel to the hub assembly. They protrude through the wheel’s mounting holes and are tightened using lug nuts.

Types of Wheel Hubs:

In addition, wheel hubs come in different types, each offering specific advantages and applications. Understanding the various types can help you make informed decisions regarding maintenance or replacement. You can contact Xtreme Mudder Wheels for one of the best wheel hubs. Hence, the three primary types of wheel hubs are:

- Bolt-On Wheel Hubs:

Bolt-on wheel hubs are separate components that can be easily replaced when necessary. They are commonly found in older vehicles and are secured to the axle using bolts. Bolt-on wheel hubs allow for individual repairs or upgrades without replacing the entire wheel hub assembly.

-

Unitized Wheel Hubs:

Unitized wheel hubs, or hub assemblies, combine the wheel hub, wheel bearings, and other components into a single unit. These pre-assembled units are often used in modern vehicles and simplify installation and replacement processes.

-

Integrated Wheel Hubs:

Integrated wheel hubs are typically found in vehicles with front-wheel drive. This design integrates the wheel hub and wheel bearing assembly into a single unit. Moreover, integrated wheel hubs offer improved efficiency, compactness, and ease of installation.

Wheel Hub Maintenance:

Furthermore, proper maintenance of wheel hubs is crucial for ensuring their longevity, performance, and safety. Here are some essential maintenance practices to keep in mind:

-

Regular Inspection:

It is important to visually inspect the wheel hubs for any signs of damage, such as cracks, corrosion, or loose components. Inspect the hub flange, studs or bolts, and the area around the wheel bearings.

-

Lubrication:

Wheel bearings require proper lubrication to reduce friction and prevent premature wear. Follow the manufacturer’s recommendations for the type and frequency of lubrication. Over time, lubricants may break down, so periodic re-lubrication is necessary.

-

Wheel Bearing Replacement:

Wheel bearings have a limited lifespan and may need to be replaced at some point. If you experience wheel noise, excessive play, or vibrations, it could indicate worn-out wheel bearings. Moreover, prompt replacement is crucial to prevent further damage and ensure safe operation.

-

Wheel Alignment:

Proper wheel alignment helps distribute the vehicle’s weight evenly across all four wheels, reducing stress on the wheel hubs. Regular wheel alignment checks and adjustments can prevent premature wear on the wheel hubs and other suspension components.

-

Timely Repairs:

Suppose you notice any issues with the wheel hubs, such as loose studs, damaged flanges, or abnormal noise. In that case, it is essential to address them promptly because ignoring these problems can lead to further damage and compromise the vehicle’s safety.

Common Wheel Hub Issues:

Understanding standard wheel hub issues can help you identify problems early on and seek appropriate repairs. Some common issues include:

- Wheel Bearing Failure:

Over time, wheel bearings can wear out, leading to excessive play, noise, and vibrations. So, neglecting worn-out wheel bearings can result in wheel detachment and pose a significant safety risk.

-

Damaged Hub Flanges:

Harsh impacts, such as hitting a pothole or curb, can cause damage to the hub flange. Cracked or bent flanges can affect the wheel’s attachment and lead to improper wheel alignment.

-

Loose or Broken Studs/Bolts:

If the wheel studs or bolts become loose or broken, it can cause the wheel to wobble or become detached. Regularly checking the tightness of the studs or bolts is essential for maintaining wheel stability.

-

Corrosion:

Wheel hubs are susceptible to corrosion, especially in regions with salted roads or high humidity. Corrosion can weaken the hub assembly and compromise its structural integrity. So, regular cleaning and applying protective coatings can help prevent corrosion.

Conclusion:

Wheel hubs are vital components of a vehicle’s assembly, providing load-bearing support, facilitating smooth rotation, and transmitting power from the axle to the wheels. So, understanding the basics of wheel hubs and their maintenance requirements is crucial for every vehicle owner. Regularly inspecting and maintaining wheel hubs, addressing issues promptly, and seeking professional assistance when needed can ensure the optimal performance, longevity, and safety of your vehicle’s wheel assembly.

Read Also: Roaring to Victory: Land Rover Discovery Si6 Reigns Supreme as Four Wheeler SUV 2018

FAQs

How do wheel hubs work?

Wheel hubs allow the wheel to rotate freely while maintaining a secure connection to the vehicle’s axle. The hub is attached to the axle using bolts or studs, and the wheel is mounted onto the hub using lug nuts. Inside the hub, wheel bearings are installed to reduce friction and support the wheel’s rotation. As the vehicle moves, the hub and the wheel rotates around the stationary axle, providing smooth and controlled movement.

What are the signs of a failing wheel hub?

Several indicators suggest a potential problem with a wheel hub. Common signs of a failing wheel hub include excessive or unusual noise, such as grinding, roaring, or clicking sounds, especially when turning; vibration felt through the steering wheel; uneven tire wear; steering misalignment; and a loose or wobbly feeling in the wheel. If you experience any of these symptoms, having your wheel hubs inspected and serviced promptly is essential to prevent further damage or safety risks.

Can I drive with a damaged wheel hub?

Driving with a damaged wheel hub is highly discouraged. A compromised wheel hub can lead to severe consequences, such as wheel detachment, loss of control, or even accidents. Suppose you suspect a problem with your wheel hub. In that case, it is crucial to have it inspected and repaired by a qualified mechanic as soon as possible to ensure your safety and the integrity of your vehicle’s performance.

How often should wheel hubs be inspected or serviced?

Regular maintenance and inspection of wheel hubs are essential to identify any potential issues before they worsen. As a general guideline, having your wheel hub inspected at least once a year or as specified by your vehicle’s manufacturer is recommended. However, if you notice any unusual symptoms or experience an impact or collision, it is advisable to have your wheel hubs checked immediately, regardless of the regular maintenance schedule.

Can I replace a wheel hub myself?

Replacing a wheel hub requires proper knowledge, tools, and experience. It is a complex task that involves disassembling the wheel assembly, removing the old hub, and installing a new one correctly. To ensure safety and avoid any damage to your vehicle, it is recommended to have wheel hub replacements performed by a skilled automotive professional with expertise in this specific area.

Remember, if you have any concerns or questions about your wheel hubs, it is best to consult a qualified mechanic or an automotive specialist who can provide accurate guidance and address your specific needs.